LiteBite

LiteBite

The compact fryer that revolutionizes your way of working

In a sector where every centimeter matters and every second counts, LiteBite is born — the professional fryer designed to meet the real needs of modern foodservice.

All-in-one: efficiency, safety, and ease of use

Whether you run a fast food restaurant, a dark kitchen, or a high-turnover outlet, Lite Bite is the compact fryer that’s changing the way kitchens work: it optimizes space, streamlines workflows, and ensures maximum operator safety, while making staff training easier.

Engineered to deliver consistent results at scale and reduce both routine and preventive maintenance costs, LiteBite consumes less energy and supports a more sustainable kitchen — without compromising on frying quality.

Its smart design and four-stage air purification system make it the ideal solution for those seeking efficiency, ease of use, and professional performance — even in limited spaces.

All-in-one: efficiency, safety, and ease of use

Whether you run a fast food restaurant, a dark kitchen, or a high-turnover outlet, Lite Bite is the compact fryer that’s changing the way kitchens work: it optimizes space, streamlines workflows, and ensures maximum operator safety, while making staff training easier.

Engineered to deliver consistent results at scale and reduce both routine and preventive maintenance costs, LiteBite consumes less energy and supports a more sustainable kitchen — without compromising on frying quality.

Its smart design and four-stage air purification system make it the ideal solution for those seeking efficiency, ease of use, and professional performance — even in limited spaces.

Why choose it?

Ease of use

Thanks to its intuitive design, the system is perfect for restaurant chains, allowing all staff to work easily—even with minimal training.

Operational safety

Cool-to-the-touch exterior, even during prolonged use. Fully enclosed well to prevent splashes and accidental contact with hot oil.

Four-stage air purification

• Stainless steel grease mesh filter

• Condenser for moisture removal and air cooling

• 2 Activated carbon filters

Customizable recipes

Managing and programming your recipes becomes effortless thanks to a clear and user-friendly panel.

Characteristics

Made of AISI 304 and 316 stainless steel

POWER: 3kW, single-phase

WELL CAPACITY: 14 liters

BASKET CONFIGURATION: single 800g, double 400+400g

DIMENSIONS: 540x700x810mm

WEIGHT: 40 kg

HEATING SYSTEM: armored heating elements.

Specifications

- Control panel with recipe programming.

- Duct to direct the outgoing air flow.

- Safety lock for access to the air purification system.

- Basket available in single or double version.

- Single or double chute for ready-to-serve foods.

- Display for real-time monitoring of the machine's functions.

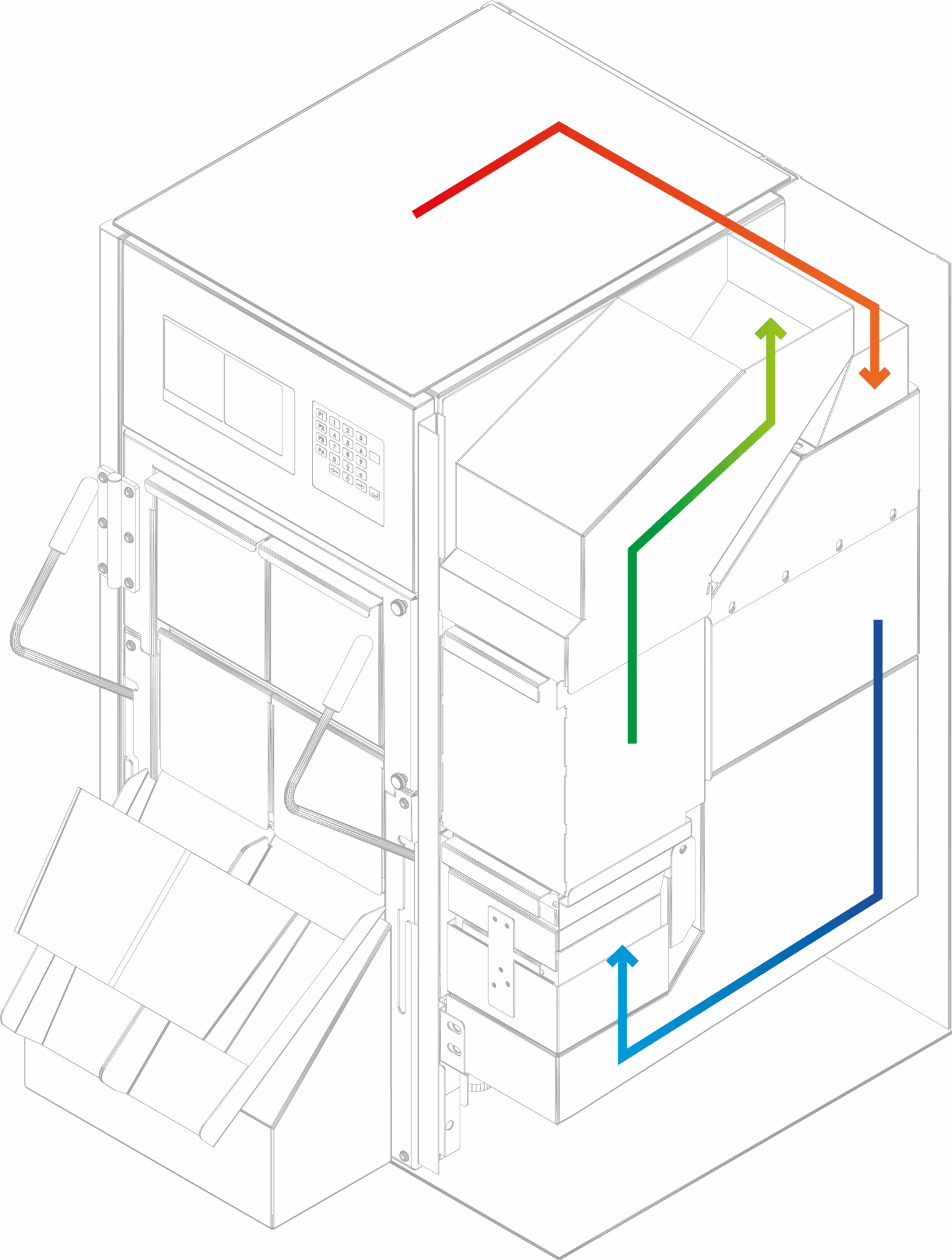

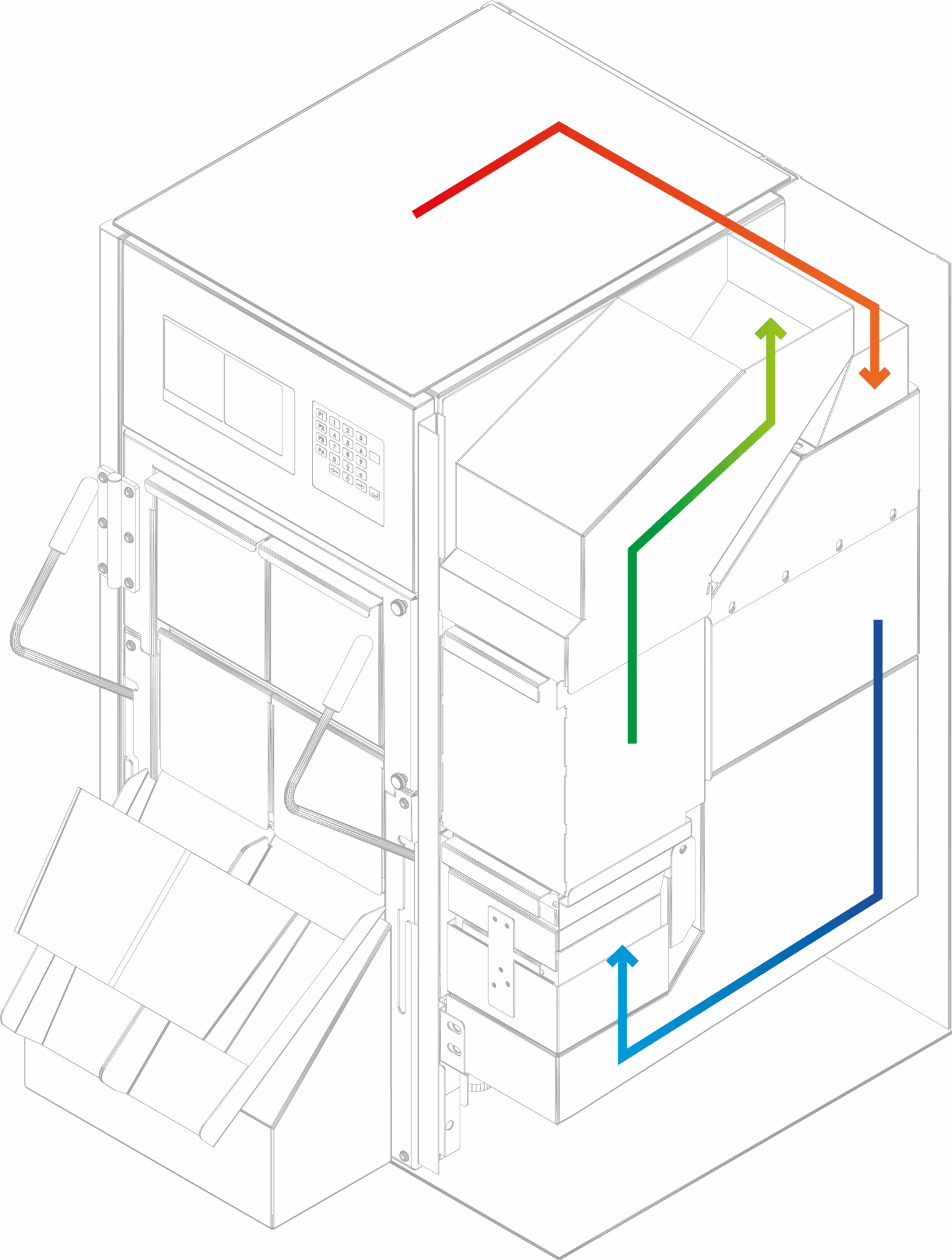

Air purification

The filtration system integrated into the Lite Bite fryer is designed to ensure effective air purification and a significant reduction of odors through a four-stage process:

- Stainless steel grease filter

- Cooling and dehumidifying condenser

- Activated carbon filter – first stage

- Activated carbon filter – second stage

Air purification

The filtration system integrated into the Lite Bite fryer is designed to ensure effective air purification and a significant reduction of odors through a four-stage process:

- Stainless steel grease filter

- Cooling and dehumidifying condenser

- Activated carbon filter – first stage

- Activated carbon filter – second stage

Beyond frying: efficiency, taste, and safety

Operational efficiency and workplace environment protection

Cooking times comparable to traditional fryers, with superior results on certain products. The enclosed vat reduces external contamination and keeps the environment clean and safe.

Even cooking and flawless results

The heated and ventilated chamber keeps the oil fluid and ensures optimal draining, reducing greasiness and preserving the integrity of the food, preventing it from breaking during frying.

Maximum performance and food safety

Cooking in a closed environment preserves flavors, enhances the organoleptic profile of foods, and ensures core temperature (72–78°C in about 2 minutes) is reached, in compliance with HACCP standards.*

Do you want to keep up to date with Silko news?

Subscribe to our newsletter!